EXTERNAL STRUCTURAL REPAIRS TO BEAMS & COLUMNS BY POLYMER BUILT UP TECHNIQUE

Break open the structural member to expose reinforcement steel & dispose off the debris arising from the same. Clean the exposed reinforcement steel thoroughly by removing rust / scaling by chiseling / tapping / wire brushing. Provide & apply rust converter to the exposed steel & allow drying for 24 hours. Provide & apply protective coat of slurry of Polymer Emulsion: cement (1: 1½) to the reinforcement steel.APPLICATION OF RUST PASSIVATOR:

The reinforcement rods must be thoroughly cleaned using a chisel, scrapper, and wire brush. The rust passivator is to be applied carefully on the exposed dry surfaces of the reinforcement rods with a brush or cloth. The passivator must be applied as per the manufacturer specifications .Allow air drying for 24 hours before any further treatment is done on this after cleaning.APPLICATION OF MORTAR/CONCRETE

Preparation of surface:

A good base or foundation shall be prepared for successful application of mortar/concrete. All unsound/weak concrete material shall first be removed by the contractor up to the required depth as directed by engineer. After it has been ensured that the surface which mortar/concrete is to be bonded is sound, it shall be cleaned off all loose and foreign material by means of sand blasting or stiff wire brushing as instructed by engineer. All dust and loose particles resulting from such pre-treatments shall be removed oil free air blast.Bonding slurry and application:

The contractor shall wet down the surfaces ensuring that they are saturated but free of surface water. Bonding slurry shall be prepared by mixing thoroughly 2 parts of cement to 1 part of water to a lump-free consistency.Application of cement mortar/concrete:

Cement shall be carried out in efficient concrete mixer. However, the engineer may allow hand mixing in case total weight of mix per batch is less than 50 Kgs. In case of hand mixing, the contractor shall mix 10% additional cement.

CURING:

New concrete shall be maintained damp for a period of 2 weeks minimum. . New plaster shall be cured at least 3 times a day for a period for a not less than 10 days. The 1st coat of plaster shall be cured for a period not less than 3days. If required the surface shall be maintained damp using a wet hessian cloth.

FIRST COAT OF ICI PAINT WEATHER SHIELD ACRYLIC PAINT

FIRST LAYER OF CEMENT PLASTER AT NEHRU SCIENCE CENTER

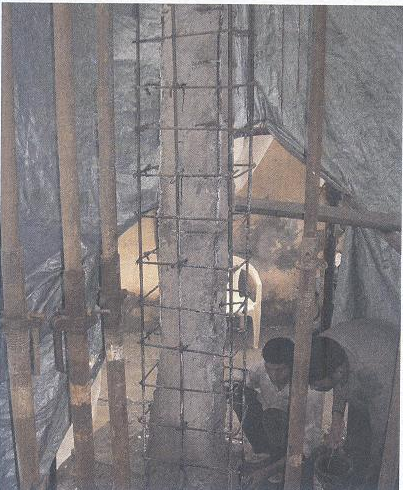

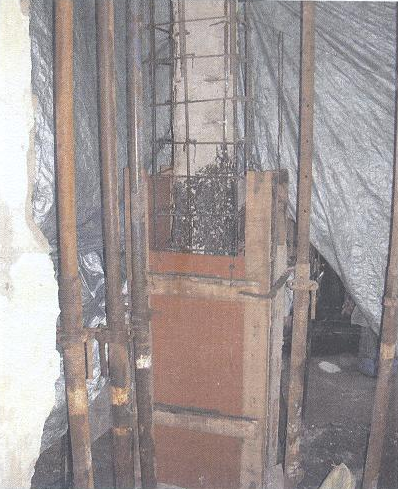

JACKETING ACTIVITIES

Breaking & Excavation of floor to plinth Beam

Providing & fixing steel props for support, & fixing new reinforcement steel wherever necessary with shear connector

Providing shuttering (form work) pouring of cement concrete / micro concrete

022-29272402

022-40131959

STRUCTURAL REPAIRS

- Home

- /

- Our Services

- /

- STRUCTURAL REPAIRS